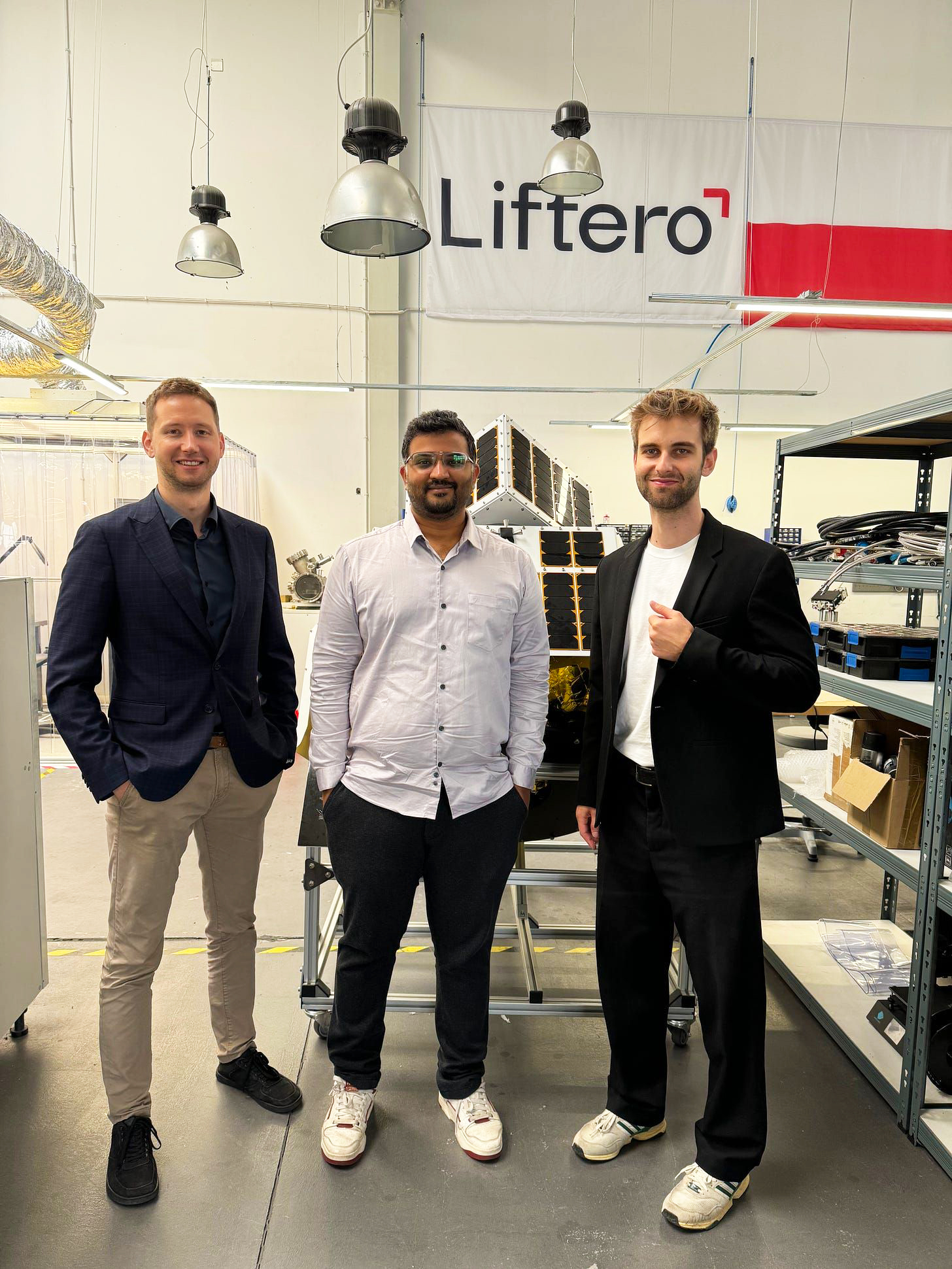

Liftero has signed a contract with OrbitAID, an Indian space company focused on bringing satellite refuelling to the space market.

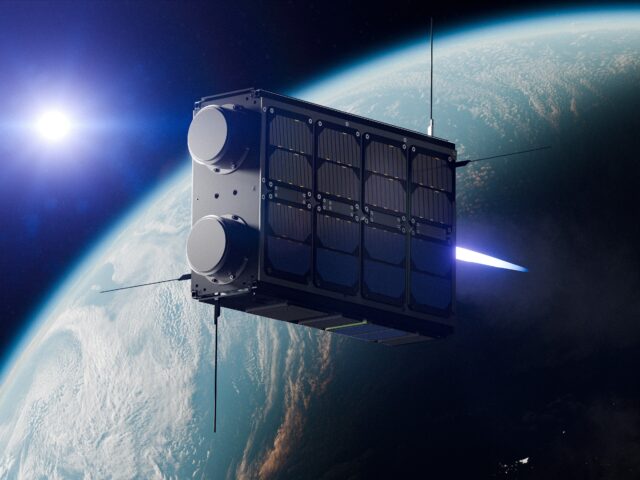

Liftero will provide a propulsion system for OrbitAID’s first mission, set to launch on an Indian PSLV in the first half of 2025. The BOOSTER system will be tailored to meet OrbitAID’s specific needs, as the mission involves an in-space demonstration of docking and refueling technology. Liftero will deliver the system in under 3 months—a record timeframe.

“OrbitAID is moving fast with their development, and we share that mindset. The timeline is ambitious, but we’re confident we can deliver a reliable system. Our main goal is the rapid delivery of scalable, reliable propulsion, and we’re excited for the chance to demonstrate our capabilities,” said Tomasz Palacz, Liftero CEO.

This news comes shortly after Liftero’s in-orbit demonstration mission for their BOOSTER propulsion system, scheduled for Q1 2025.

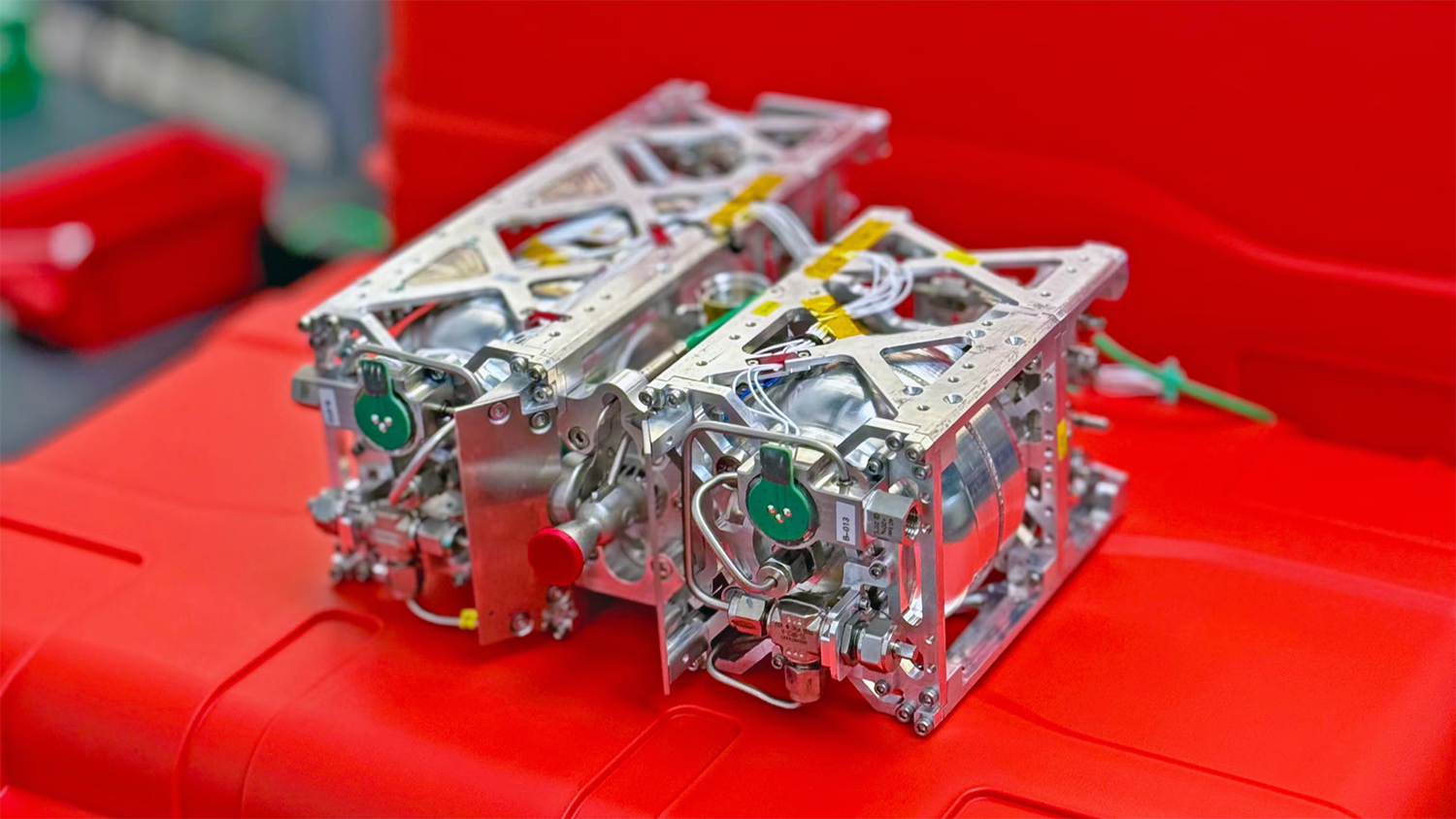

The propulsion demonstrator, developed for the RED5 mission, has passed all qualification testing and is now awaiting final satellite integration ahead of its launch onboard Transporter-13.

Liftero designs the BOOSTER propulsion system to be scalable and modular, using common components as building blocks. This approach makes it easy to configure the system to meet customer needs while avoiding costly and time-consuming custom engineering.

“BOOSTER’s modular design lets us meet very specific customer requirements without the need for custom engineering. For example, we can build OrbitAID’s system quickly, as 80% of the solutions were developed for RED5. The rest is tailored for their refueling mission,” said Przemysław Drożdż, Liftero COO.

Liftero awaits its in-orbit demonstration, a crucial step toward scaling production capabilities, aiming to deliver reliable propulsion 3x faster than the industry standard.

The company is able currently to build and test singular systems, but the BOOSTER introduces not only a high-end green propulsion but also a suite of processes, allowing to reduce manual engineering, number of manufacturing processes and simplify the supply chain.

“In our development, we’ve been focused on production and delivery from day one. That’s why we don’t obsess over tweaking specific numbers on a datasheet. Sure, we could gain a few extra seconds of specific impulse, but that’s not where the secret sauce lies. Despite the seemingly saturated propulsion market, on-time delivery of large amounts of propulsion for constellations remains a significant challenge. Our goal is to tackle this problem and meet the industry’s demand,” said CEO Tomasz Palacz.