Liftero has signed a contract with the European Space Agency under the GSTP programme, within the Advanced Manufacturing framework, to improve its metal 3D-printed combustion chambers for the space-proven BOOSTER propulsion system.

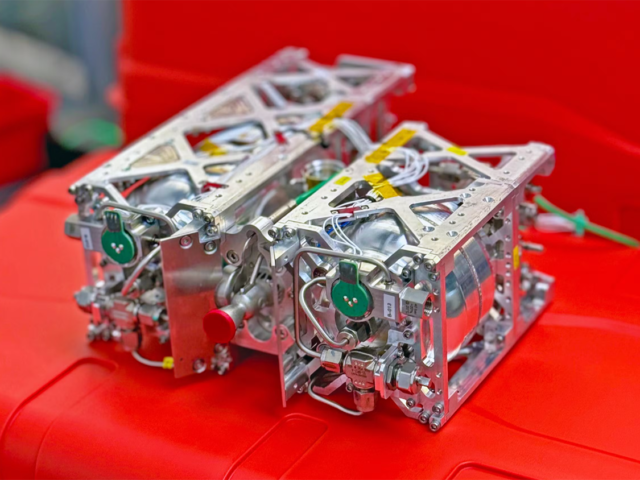

Together with its partner — Progresja SA — Liftero will lead the project to develop and test the next generation of combustion chambers for its 1N thrusters, a key component of the BOOSTER propulsion system.

BOOSTER is a green chemical propulsion system using nitrous oxide and propane propellants — safe, affordable, and easily accessible worldwide. It’s designed for satellites in the 30–250 kg range and can be tailored in form factor, total impulse, and number of thrusters.

Although BOOSTER already operates in space, Liftero aims to provide its customers with the highest level of reliability.

In March 2025, Liftero launched the first BOOSTER unit onboard RED5 satellites (tracking: ORBASTRO-TR5) to perform an orbital demonstration of the market-ready product. The satellite platform has successfully completed commissioning, and the propulsion remains in good health. Thruster hot-fires are planned in the coming weeks.

BOOSTER will benefit from the ESA-supported development through improved manufacturing processes and combustion chamber design. The goal is not only strong performance — already proven with a 20-minute steady-state burn — but also high manufacturing quality and reliability, with the process qualified according to ECSS standards.