Liftero, aiming to provide satellite manufacturers with versatile propulsion systems that can be produced at scale, is preparing for its final test ahead of product launch.

Founded by Tomasz Palacz (CEO) and Przemysław Drożdż (COO), Liftero has been operational since 2023 and secured its first VC funding in the same year. The company developed its green chemical propulsion technology from scratch, reaching launch readiness in less than a year.

“We are excited that what started as a two-person garage project last year is now set to launch into space for a demonstration and will soon be in the hands of our customers,” said Tomasz Palacz.

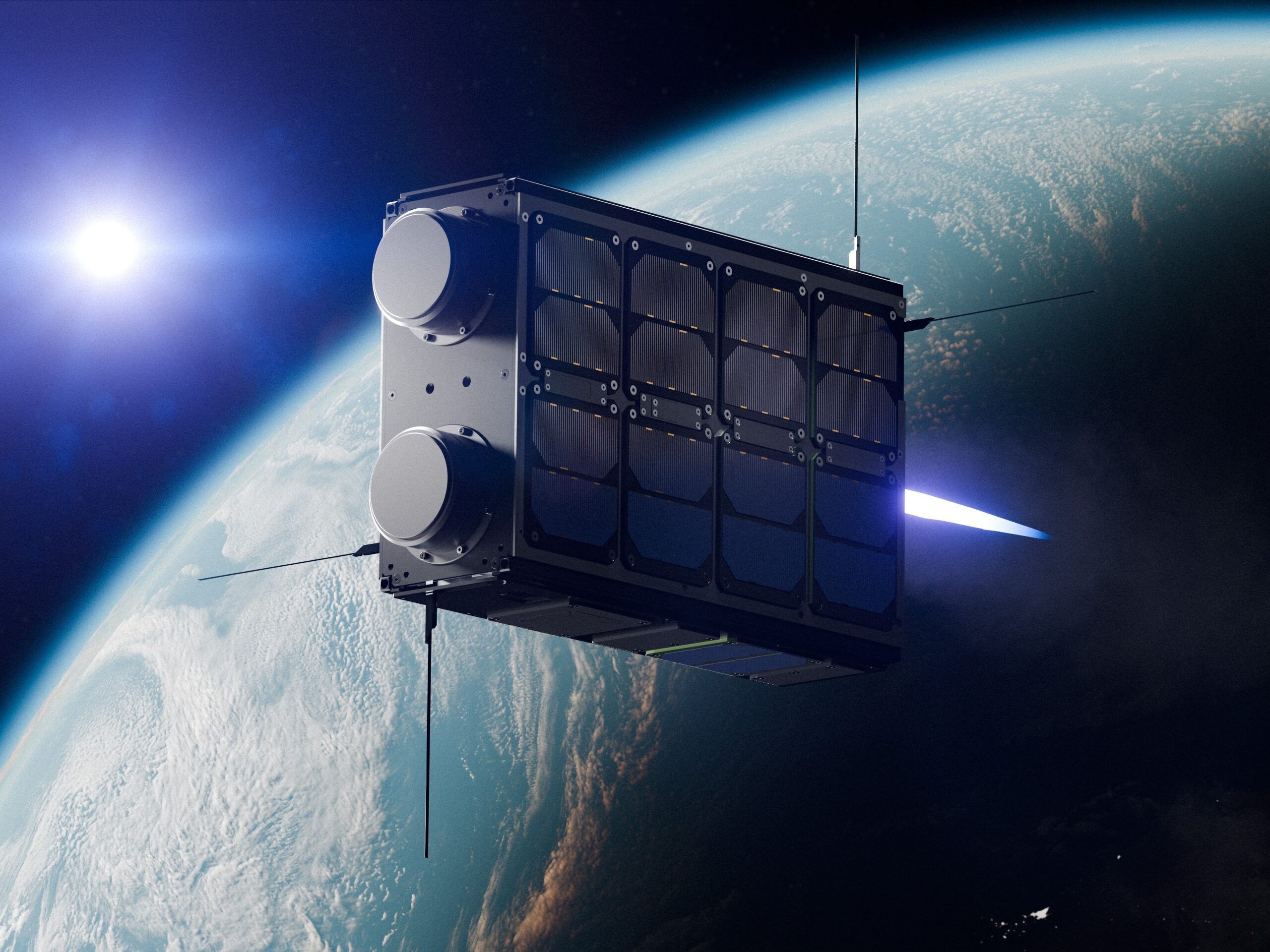

The RED5 mission, marking the inaugural flight of Liftero’s propulsion system, aims to validate its performance in orbit. A successful deployment and operation of this system will open new market opportunities for Liftero, paving the way for the commercialization of its technology.

Liftero aims to capitalize on this growth by providing satellite manufacturers with versatile, high performance propulsion systems that can be produced at scale.

“All satellites need propulsion, but we see that current suppliers are not prepared to produce such volumes and at the right quality. We see this as an opportunity for us,” said Przemysław Drożdż.

The market is changing fast, and current propulsion solutions don’t meet the needs of today’s satellites.

These systems must not only excel in performance and reliability but also offer short production times, scalability and be affordable. This is crucial to meet the needs of satellite constellations, which require hundreds or thousands of units annually—far beyond the typical capacities of conventional propulsion suppliers.

Liftero addresses these challenges by focusing not only on the propulsion technology itself, which serves as a key layer, but also on process automation and advanced manufacturing. This approach will reduce the time from first contact to propulsion delivery by three times compared to the industry standard and allow Liftero to deliver hundreds of systems per year.

The goal is to transform the satellite mobility market by redefining chemical propulsion and leveraging falling launch costs.

While chemical propulsion has dominated space since its inception, electric propulsion has rapidly gained market share in recent decades. Its main advantage is a 4- to 10-fold increase in fuel efficiency, which significantly reduces satellite mass and launch costs. As a result, most propulsion suppliers are now prioritizing electric propulsion systems and working to miniaturize them for small satellites.

However, electric systems produce low thrust, resulting in very slow orbit changes that take valuable time away from the satellite’s mission, and chemical propulsion could make its big comeback.

The use of high-thrust chemical propulsion results in a tenfold reduction in maneuvering time, saving satellite operators both time and money and increasing their ROI.

With the decreasing cost of launching payloads into space, thanks to companies like SpaceX, satellite manufacturers and operators no longer need to compromise by choosing electric propulsion just to save on launch mass. When launch prices are low, it makes more sense to choose the option that offers the best performance for the mission. This makes chemical propulsion a great choice when being fast and on time is key in today’s world.

Until recently, small satellites, which make up more than 95% of all spacecraft launched, couldn’t use chemical propulsion because it relies on highly toxic fuels that are banned on most launches.

That’s why Liftero has developed its propulsion system with green propellants that are safe, inexpensive and readily available, allowing satellite manufacturers to use it in rideshare launches without restrictions.

Liftero’s product combines high performance with a scalable and modular architecture that can be easily industrialized.

Traditionally, most propulsion systems on the satellite market were custom-designed for each customer, leading to high costs and long production times. This approach is not sustainable for scalable production.

Using common components as building blocks, advanced manufacturing techniques such as metal 3D printing and process automation, Liftero can rapidly develop propulsion systems tailored to specific needs – and produce them at scale.

“It’s like with smartphones,” said Przemysław Drożdż. “You have one model with different versions. Each version might have a different size, battery, or camera, but it’s essentially the same hardware and software. We’re going to do the same with propulsion systems”.

Liftero uses nitrous oxide and hydrocarbon propellants that are self-pressurizing, eliminating the need for complex pressurization systems. The upcoming RED5 mission will test their 1 N thruster, with plans to offer thrusts up to 200 N. Their initial product provides a total impulse of up to 25 kNs with a flexible number of thrusters, and the company aims to develop larger systems with a total impulse of up to 500 kNs.

“Nitrous-based propulsion isn’t perfect, but after looking at all our options, it’s the best choice given what the market needs right now. There are more performant propellants out there, but they have some serious drawbacks, and nitrous ultimately comes out on top. We’re also seeing the market trend in this direction, with other companies successfully launching nitrous-based propulsion systems into space,” said Tomasz Palacz.

As potential customers line up for 2025 and 2026 missions, Liftero plans to scale its production capabilities.

The company remains focused on the upcoming RED5 mission, the success of which will pave the way for fulfilling orders from customers interested in Liftero’s products. The RED5 mission is planned for a one-year operation. However, once enough data confirms the technology works in orbit, Liftero will begin scaling up its production capabilities.

“Propulsion systems are just tools in the hands of satellite operators, who use them to generate value across industries here on Earth. We’re here to make their work easier with high-performance propulsion systems they can rely on to be delivered on time, in the right quantity and quality,” said Tomasz Palacz. “We get that satellite manufacturers don’t want to be experts in every propulsion technology to choose the most suitable one for their specific mission. Space is hard, and we’re here to make it just a little easier.”